|

|

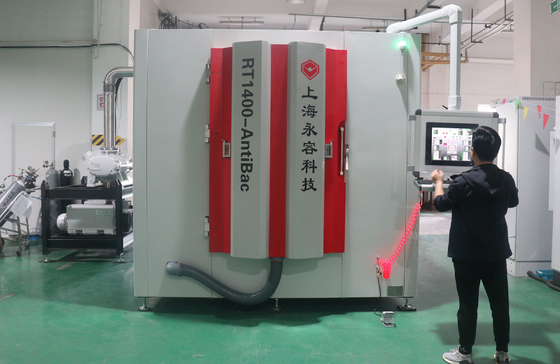

| Brand Name: | ROYAL TECHNOLOGY |

| Model Number: | RTAC-1400M |

| MOQ: | 1 |

| Price: | NEGOTIABLE |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5 sets/month |

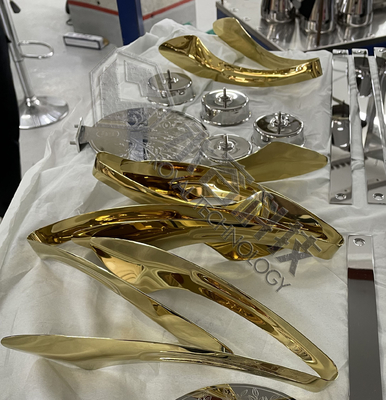

PVD ZrN (zirconium nitride) gold coatings are another type of PVD coating that replicates the appearance of gold. ZrN coatings offer a gold-like color and finish, similar to PVD TiN gold coatings.

Here's some information about PVD ZrN gold coatings:

PVD ZrN gold coatings offer an alternative to traditional gold plating or solid gold, providing a cost-effective and durable solution with a visually appealing gold-like appearance. The coatings are widely used in various industries to achieve a luxurious and elegant finish on different products.

What are the advantages of using PVD ZrN gold coatings over traditional gold plating?

Using PVD ZrN gold coatings instead of traditional gold plating offers several advantages:

Durability: PVD ZrN gold coatings are highly durable and resistant to wear, corrosion, and tarnishing. They provide a protective barrier on the substrate, extending the lifespan of the coated product. In contrast, traditional gold plating can wear off over time, requiring re-plating to maintain the gold appearance.

Consistency: PVD ZrN gold coatings offer a consistent gold color and finish across the entire coated surface. Traditional gold plating can sometimes result in uneven color distribution or variations in appearance due to factors like plating thickness and surface irregularities.

Thickness Control: PVD coatings allow precise control over the thickness of the deposited layer. This enables manufacturers to achieve the desired color and appearance consistently, ensuring a uniform and aesthetically pleasing gold finish. In contrast, traditional gold plating thickness can be challenging to control, leading to inconsistencies in the final appearance.

Environmental Benefits: PVD coatings, including ZrN gold coatings, are a more environmentally friendly alternative to traditional gold plating. PVD processes are typically carried out in a vacuum, minimizing the release of harmful chemicals and reducing waste generation compared to electroplating processes used in traditional gold plating.

Cost-Effectiveness: PVD ZrN gold coatings can be a cost-effective solution compared to traditional gold plating. While solid gold and gold plating can be expensive due to the high cost of gold, PVD coatings provide a gold-like appearance at a fraction of the cost, making them more accessible for various applications.

Compatibility: PVD ZrN gold coatings can be applied to a wide range of substrates, including metals, ceramics, and some plastics. This versatility allows for the application of the gold finish on diverse products, expanding the range of items that can benefit from the luxurious appearance of gold.

By utilizing PVD ZrN gold coatings, manufacturers can achieve a durable, consistent, and visually appealing gold-like finish on their products. These coatings provide advantages in terms of durability, uniformity, thickness control, environmental impact, cost, and compatibility, making them a desirable alternative to traditional gold plating.

Royal Technology provides standard models of PVD ZrN coating machines for various sizes of work pieces

| Description | RT1000-DLC | RT1000-IPG | RT1250 | RT1612 |

| Technical Advantages | Plug-in Integrated system for fast installation Short cycle times for decorative coatings High yield of coating products High density and excellent uniformity High abrasion and corrosion resistance More than aesthetic but functional performance |

Higher volume Multiple deposition sources for fast deposition Combined arc and several sputtering cathodes : arc for good adhesion amd strong bonding layer, sputtering deposition for specific coatings. |

||

| Major Applications | Black DLC coatings on medical insutrments, jewelry, watch parts. 24K pure gold/18K gold alloycoatings on luxury products: brands metal accessries etc. Microelectronics industry |

Medium and larger workpieces: SS cutlery, door handles, bathroom fittings, automotive components, sports, house appliances , kitchenware and spectral frames etc. | ||

| Deposition Chamber | φ1000 * H1000mm | φ1250 * H1250mm | φ1600 * H1250mm | |

| Load Diameter (Max.) |

6*φ250mm 12*φ120mm |

8*φ270mm 10*φ230mm | 10*φ300mm 16*φ200mm | |

| Load Height ( Effective) |

650mm | 900mm | 900mm | |

| Deposition Cathodes | 5 arc + 4 pairs MF cylinder sputter | Option A: 8 arc + 1 set DC planar sputter; Option B: 5 arc + 2 sets DC planar sputter |

7 arc + 3 (or 4) pairs of MF cylinder sputters | 12 arc + 4 (or 6 ) pairs of MF cylinder sputters |

| Operation & Control System | Siemens PLC + Industrial Computer + RoyalTech. Operation Program Available for remote operation and diagnosis |

|||

These configurations are standard, for a specific developing market and new special coatings, the customized configurations and modifications are available on requests.

We provide comprehensive technical support and service for our PVD Vacuum Coating Machine. Our support services include:

We offer these services in order to ensure that our customers get the most out of their investment in the PVD Vacuum Coating Machine. Our dedicated team of technical experts is available to provide assistance in any way needed.

PVD Vacuum Coating Machine is securely packaged and shipped with sturdy cardboard boxes and materials to ensure the product arrives safely and undamaged. Special care is taken to ensure that the product is not damaged during the packaging and shipping process.