|

|

| Brand Name: | ROYAL |

| Model Number: | RTSP1200 |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C,T/T |

| Supply Ability: | 8 sets per month |

Deposition of Tantalum, Gold precious metals by Sputtering

Sputtering is widely used to deposit refractory metals like tantalum, titanium, tungsten, niobium, which would require very high temperatures of deposition, and precious metals: Gold and Silver and which is also used for deposition of lower melting points metals like copper, aluminum, nickle, chrome etc.

Tantalum is most used in the electronic industry as a protective coating because of its good resistance to erosion.

Sputtered tantalum films are widely used in the

1. Microelectronics industry as the films can be reactively sputtered and thus resistivity and temperature coefficient of resistance can be controlled;

2. Medical instruments like body implants for its highly biocompatability property;

3. Coatings on corrosion resistant parts, such as thermowells, valve bodies, and fasteners;

4. Sputtered tantalum can be also be used as an effective corrosion resistance barrier if the coating is continuous, defected and is adherent to the substrate is intended to protect.

Royal Technology’s standardized Tantalum sputtering deposition system: RTSP1000 model.

Tantalum sputtered film properties:

Low resistivity

High corrosion and wear resistant coatings on surface that are subjected to high stresses and harsh chemical and erosive environment.

Design features:

Robust Design, Stable Quality, Fast Cycle, High Precision System

|

Main Configurations |

|

|

MODEL |

RTSP1000 |

|

TECHNOLOGY |

DC magnetron sputtering + Cathodic arc plating |

|

CHAMBER MATERIAL |

Stainless Steel (S304) |

|

CHAMBER SIZE |

Φ1000*1600mm (H) |

|

CHAMBER TYPE |

D shape, cylindrical chamber |

|

ROTATION RACK & JIG SYSTEM |

Satellite driving or central driving system |

|

POWER SUPPLIES |

DC Sputtering Power Supply: 2~4 sets Ion Source: 1 set |

|

DEPOSITION MATERIAL |

Ti/Cr/TiAl, Ta, Au, Ag, Cu etc. |

|

DEPOSITION SOURCE |

Planar Sputtering Cathodes + circular arc cathodes |

|

CONTROL |

PLC(Programmable Logic Controller) + Touch Screen |

|

PUMP SYSTEM |

Rotary Vane Pump: SV300B - 1 set (Leybold) |

|

Roots Pump: WAU1001 - 1 set (Leybold) |

|

|

Holding Pump: D60C - 1 set (Leybold) |

|

|

Magnetic Suspension Molecular Pump: |

|

|

GAS MASS FLOW CONTROLLER |

2 channels: Ar and N2 |

|

VACUUM GAUGE |

Inficon or Leybold |

|

SAFETY SYSTEM |

Numerous safety interlocks to protect operators and equipmen |

|

HEATING |

Heaters: 20KW. Max. temp.: 450℃ |

|

COOLING |

Industrial Chiller (Cold Water) |

|

POWER MAX. |

100KW (Approx.) |

|

AVERAGE POWER CONSUMPTION |

45 KW (Approx.) |

|

GROSS WEIGHT |

T (Approx.) |

|

FOOT PRINT |

( L*W*H) 4000*4000 *3600 MM |

|

ELECTRICAL POWER |

AC 380V/3 phases/50HZ / 5 line |

Equipment Structure:

Coating System Structure: Vertical orientation, octagonal structure, 2 doors for easy access.

Environmentally friendly system, no hazardous wastes.

Total integration, modular design

Commercialized and standardized for industrial mass production

Extremely efficient ion source for strong adhesion and high ionization.

Easy Operation: Touch screen + PLC control, one touch operation

Special design of Carousel system for high uniformity deposition.

High productivity and stability, working 24/7 a week.

Flexible, matches to various sizes of plates

Key components

![]()

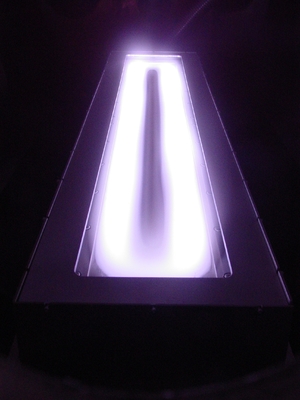

Ion source for assisted depositon process:

![]()

Ion source for plasma iteching process:

![]()

The RT1200-FCEV machine is a batch model sputtering system, which can deposit various hard coatings, soft coatings, compound films and solid lubricating films on the metallic and non-metallic materials substrates. Applied to industries of Hydrogen Fuel Cell vehicles, photonic products, aerospace and other new energy industries.

Performances of the deposition films:

To improve the conductivity of surface;

High corrosion resistance;

High wear resistance;

High hardness

Hydrophobic composition film and other functional films

Available for compound coatings: metallic and non-metallic films.

Film thickness range from 100nm to 12μm, thickness tolerance ±5%

Strong adhesion.

Low tempering parts surface hardening treatment.

Type:

Vertical orientation, octal structure, 2-doors (front and back)

Design advantages:

Contact us for more details. Royal Tech team is honored to serve you with our best service and knowleage.