|

|

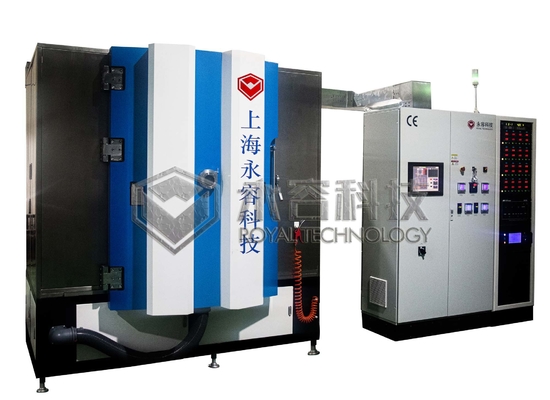

| Brand Name: | ROYAL TECHNOLOGY |

| Model Number: | RT1600-PAPVD |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets per month |

Royal Technology provides innovative PAPVD coating technology and equipment, which can get rid of the electroless roughening process on engineering plastic parts.

Benefits

Environmentally friendly

Deposited thickness is controllable

Stronger adhesion

Water consumption saiving

Lower cost of craftmanship

Short cycle time

Applications:

Automotive industry is one typical application, “It is a disruptive coating method , we are so happy to say Good-bye to electropless process”, Mr. Woo said excitingly who provides the automotive plastic components from Shanghai city.

Substrates are applied with like engineering plastics: PPS, ABS, ABS+PC, PA, PEEK etc.

![]()

PPS products with PVD Nickle, PVD Chrome plating

![]()

Plasma Assistant PVD Deposition

LTAVD , Low Temperature Arc Vapor Deposition, also named as Low Temperature arc ion plating. It is applied with low temperature resistance plastic workpieces for decorative coatings:

Consumer electronics: cellphone, computer, television, cameras;

Home appliances: air conditioners, washing machine, vacuum cleaners

Bathroom and kitchen fixtures;

Automotive industry: plastic interior trims and exterior trims, LOGO

![]()

![]()

ABS Mirror Gold ABS Mirror Black

![]()

ABS Copper (Rose Gold) - Mirror and Matte Copper Plating

.![]()

ABS Brown Coatings - Matte Brown

![]()

![]()

ABS Matte Black ABS Matte Gold - car handle

Technical Specifications

|

Description |

RT1600-PAPVD | RT1600-LTAVD |

| Applications | Engineering plastics: PPS, ABS, ABS+PC, PA, PEEK etc. |

LTAVD , Low Temperature Arc Vapor Deposition, also named as Low Temperature arc ion plating. It is applied with low temperature resistance plastic workpieces for decorative coatings: Consumer electronics: cellphone, computer, television, cameras; Home appliances: air conditioners, washing machine, vacuum cleaners Bathroom and kitchen fixtures; Automotive industry: plastic interior trims and exterior trims, LOGO

|

| Deposition Chamber |

φ1600 * H1600mm

|

|

|

Load Diameter (Max.) |

10*φ300mm 16*φ200mm

|

6*φ420mm + 8*φ350mm

|

| Load Height ( Effective) |

1200mm | |

| Deposition Sources | 14 arc cathodes + 1 set planar sputtering cathode | 14 arc cathodes |

| Pulsed Bias Power | Max. 30KW | |

| Footprint (L*W*H) | 6500*6000*4300mm | |

| Power Consumption |

Max. 70KW Average:40KW |

|

| Operation & Control System |

CE standard Mitsubish PLC+ Touch Screen Operation Program with backup

|

|

These configurations are standard, for a specific developing market and new special coatings, the customized configurations and modifications are available on requests.

Please contact us for more information.

Innovation is a disruptive change to the conventional technology.