|

|

| Brand Name: | ROYAL |

| Model Number: | RTSP1200 |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C,D/A,D/P,T/T |

| Supply Ability: | 6 sets per month |

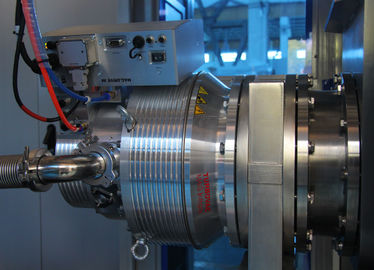

Machine Model: RT1200-FCEV

Technology: with PECVD + PVD Magnetron Sputtering Depositing: Si, Cr, graphite targets, to generate Unbalanced closed magnetic field for high density, high uniformity and excellent corrosion resistance carbon-based film.

This RT1200-FCEV high vacuum magnetron sputtering deposition system is a tailor made model which refers to the model Multi950-R&D which we have built for Shanghai University.

It is designed with Octal chamber, flexible and reliable performances are extensively used in various applications. It satisfy the coating processes require multi different metal layers: Ta, Cr, Si, Graphite, Al, Cr, Cu, Au, Ag, Ni, Sn, SS and many other non-ferromagnetic metals; plus the Ion source unit,

efficiently enhance film adhesion on different substrate materials with its plasma etching performance and the PECVD process to deposit some carbon-based layers.

Equipment Structure:

Vertical orientation, octagonal structure, 2 doors opening (front and back) for easy access.

Equipment Features:

Environmentally friendly system, no hazardous waste

High integration, modular design

Commercialized and standardized for industrial mass production

Extremely efficient ion source for strong adhesion and high ionization

Easy Operation: Touch screen + PLC control, one touch operation

With Royal Technology’s software, process parameters can be programmed, saved and reproduced

Special design of Carousel system for highly uniform deposition

High productivity and stability, working 24/7 a week

Flexible, matches various sizes of plates, for single or double sides coating

PVD & PECVD coating film performance:

To improve the conductivity of surface

High corrosion resistance

High wear resistance

High hardness

Hydrophobic composition film and other functional films

Available for compound coatings: metallic and non-metallic films

Film thickness range from 100nm to 12μm, thickness tolerance ±5% Strong adhesion

Low tempering parts surface hardening treatment

| MODEL | RT1200-FCEV | |||||||||

| MATERIAL | Stainless Steel (S304) | |||||||||

| CHAMBER SIZE | Φ1250*1350mm (H) | |||||||||

| CHAMBER TYPE | Front and back 2-doors structure, Vertical | |||||||||

| SINGLE PUMP PACKAGE | Rotary Piston Vacuum Pump | |||||||||

| Roots Vacuum Pump | ||||||||||

| Magnetic Suspension Molecular Pump | ||||||||||

| Rotary Vane Pump (Holding Pump) | ||||||||||

| TECHNOLOGY | Magnetron Sputtering, Ion Source PECVD | |||||||||

| POWER SUPPLY | Sputtering power supply + Bias Power supply + Ion Source | |||||||||

| DEPOSITION SOURCE | 2 pairs DC/RF Sputtering Cathodes + (2 pairs spare using) + Ion Source | |||||||||

| CONTROL | PLC+Touch Screen | |||||||||

| GAS | Gas Mass Flow Meters ( Ar, N2, C2H2, O2) Argon, Nitrogen and Ethyne,Oxygen | |||||||||

| SAFETY SYSTEM | Numerous safety interlocks to protect operators and equipment | |||||||||

| COOLING | Cooling Water | |||||||||

| CLEANING | Glow Discharge/Ion Source | |||||||||

| POWER MAX. | 150KW | |||||||||

| AVERAGE POWER CONSUMPTION | 75KW | |||||||||

![]()

![]()

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.